Pros of Digital Label Printing

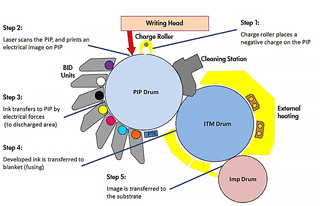

Because it’s easy to create and modify label designs and information digitally without the need for plates, digitally printed labels can be a nimble, cost-effective option for printing custom labels in smaller quantities. However, digital color label printing now has advanced capabilities that enable it to go beyond just being a solution for short runs. These include:

- Variable, randomized and personalized content

- Hyper-customization

- Anti-counterfeiting and brand protection

- Prototyping and sample production

These types of labels can include variable data such as different designs, colors, logos and information without the need to switch out plates, and minimal setup makes for a faster turnaround time. At General Data, our digital printed labels can even be finished with spot varnishes and custom die-cutting.

Plus, you can specify the exact quantity, so there’s less overall waste - a benefit from both a cost and environmental standpoint.

Cons of Digital Label Printing

While digital printing is a great choice for short label runs, it doesn’t scale as well for high-volume label production. Some digital inks or toners may also not be as resistant to abrasion, sunlight or moisture. Additionally, depending on the digital printing technology or press used, spot color matching may also not be as precise as with flexo printing, an important consideration for brands that require strict color consistency.

Pros of Flexo Label Printing

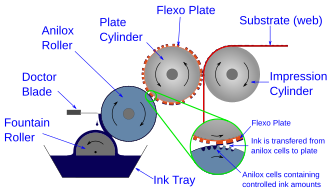

With the ability to run continuously at high speeds, flexo label printing is a highly efficient process for producing large runs of printed custom labels at low cost. It can print on a wide range of substrates, including paper and films such as BOPP, PET and PE. It also allows other printing and finishing processes to be completed in-line, including spot and pattern coatings, laminating, embossing and foil stamping.

Cons of Flexo Label Printing

While there’s no doubt that flexo printing produces a high-quality product, it is not cost-effective for short runs due to the longer and more involved set up required. When multiple designs, color changes, or changes to other printed information is required, changing out plates or inks is much more time-consuming. Flexo printing can also generate more material waste during setup and calibration.