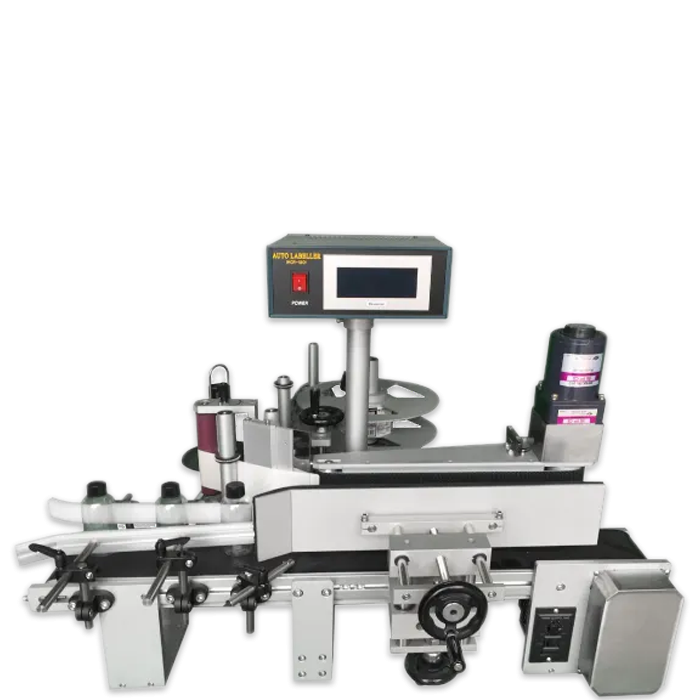

To use, an operator simply places the items to be labeled at one end of the conveyor and it travels along the label head where the label is applied. The product then enters a vertical conveyor, which rotates the bottle against a specially designed platen that adheres the label to the product. The product then exits at the other end of the table.

The Mini-Con R has a small tabletop design and is fully portable, and can be integrated into full production lines, used with feed tables and accumulation tables, or the products can be fed into the machine by an operator.

Tach-It Mini-Con R

Tach-It Mini-Con R

Features and Benefits

Title

Automatic Label Application for Cylindrical and Round Products

Text Description

The Mini-Con R is fully automated, and is designed for high productivity label application of round bottles, cans, jugs and cylindrical products

Title

Easy to Use and Set Up

Text Description

No special operator training or tools are necessary for setup, or changeover of labels or products. The unit is tabletop-designed, can be mounted to a Tach-It table and is fully portable

Title

Built-In Conveyor

Text Description

The Mini-Con R automated top label applicator has a small footprint at 57” L x 38” W, and includes a built-in 4¼” wide by 39 ½” long adjustable speed high friction conveyor. Wider conveyers are also available

Title

Fast Label Application For High Productivity Applications

Text Description

The Mini-Con R can attain speeds of up to 59 feet per minute

Title

Touch Panel Controls

Text Description

The easy-to-read touch-sensitive display panel controls include 5 memory presets and a target counter, with many other available options

Title

Exact and Consistent Label Placement

Text Description

The Mini-Con R includes a dwell timer, so you can expect consistent label placement every time. Maximum label size is 5” x 11”

Title

Additional Productivity Features

Text Description

Other advantages include an extra large roll capacity (up to 11 ½ -inch roll on a 3” core) and a stepper motor for increased reliability

Product Resources

Want To Know More?