Why The Need To Upgrade Now?

Companies who had previously deployed GHS label printing systems years ago are finding that they need to update and replace their GHS label printers for the following three key reasons:

- Production Stoppage Prevention: All mechanical devices wear out over time, and label printers are no different. Some companies have been using their original GHS label printers for 5 to 8 years. When printing GHS labels becomes a mission-critical component to shipping product, companies should retire old printing equipment and upgrade to new GHS label printers in order to prevent downtime due to malfunctioning printers.

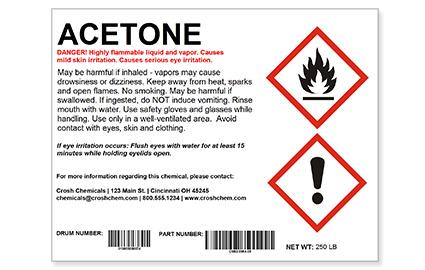

- Technology Improvement: GHS compliant label printers have significantly advanced in the last few years in the areas of speed, reliability, connectivity and cost. As GHS labels require the ability to print color, these technology advancements can significantly improve a company’s GHS labeling system.

- Cost Reduction: Updated and improved GHS label printing systems can decrease a company’s overall labeling costs. Faster and more efficient, they can reduce labor and production costs. These new GHS label printers are more reliable, which means less downtime due to printer malfunctions. Printer supplies are less expensive. Enhanced printer connectivity options give companies more flexibility for how and where they print their GHS labels. And there are now many more less expensive options for labelstock to use for printing GHS labels, especially BS5609-compliant chemical drum labels.

What Are Your Best Options?

When the GHS initiative was first introduced, companies that needed to print GHS labels had a choice of printing technologies, including thermal transfer, laser and inkjet. While all these options are still available today, digital color inkjet label printing technologies, inks and label facestocks have made significant advancements and are now the printing technology preferred by most chemical manufacturers, re-packagers, and others who regularly print GHS labels.

Many chemical companies originally purchased Epson’s C831 color label printer to print their GHS and BS5609-compliant chemical drum labels. As Epson has announced as of June 2020 they will halt the production and sale of the C-831, the C6500 is a great replacement and upgrade to the C831. One of our customers who upgraded from the C831 to the C6500 recently told us: “I like it a lot. We’ve found the C6500 a lot faster as well as providing much better print quality than either the C3500 or C831.”

I like it a lot. We’ve found the C6500 a lot faster as well as providing much better print quality than either the C3500 or C831.

Ready To Upgrade Your GHS Label Printing?

Contact the GHS labeling experts at General Data – we’ll walk you through your options and help you put together a plan for a seamless upgrade. We can supply you with everything you need for a complete GHS label printing system, including printers, labels, software, integration and service options. The end result: you’ll increase productivity and reduce overall labeling costs for your GHS label printing operation.

Ready to get started? Learn more about GHS labeling systems, or contact us.